Thermal Management Solutions for Engineers, OEMs, and Distributors in the Upper Midwest, USA

- Key Takeaways: Thermal Solutions At a Glance

- What Is Thermal Management? A Quick Introduction…

- Getting the Right Thermal Management Products Quickly

- Thermal Management Products by Category

- Thermal Management Products by Industry

Key Takeaway: Thermal Solutions At A Glance

Manufacturer |

Product Categories |

Applications/Industries |

ebm-papst |

Fans, Blowers, Motors |

HVACR, IT, Computing & Data, Industrial Equipment |

Fantastic |

HVLS fans |

Commercial and industrial climate control, energy savings |

Laird Performance Materials (Dupont) |

Thermal Interface Materials (TIMs), Liquid Dispensable Gap Fillers, Gap Filler Pads, Phase Change Materials |

Medical Devices, Military & Aerospace, Power Generation |

Laird Thermal Systems |

Thermoelectric Coolers, Liquid Cooling Systems, Heat Exchangers, Custom Solutions |

Medical Devices, Military & Aerospace, Industrial Equipment |

Mersen |

Heat Sinks, Heat Pipes, Cooling Plates |

Heavy Equipment, Power Generation & Solar Energy, Transportation & Rail |

nVent Schroff |

19” Rack Fan Trays, Coolant Distribution Units (CDUs), In-Rack Coolers, Heat Exchangers, In-Row Coolers |

IT, Computing & Data, Industrial Equipment |

What Is Thermal Management? A Quick Introduction…

For those who aren’t sure they’ve come to the right page—or for you thermal engineers with children, friends, or family who want some help explaining what you do—here’s our brief definition.

Definition of Thermal Management

Thermal management in manufacturing is all about keeping things cool (and occasionally warm!) so everything works smoothly. It refers to the methods and technologies used to control the temperature of products and systems to ensure they operate efficiently and reliably.

It typically involves dissipating excess heat generated by electronic components or mechanical processes to prevent overheating, which can lead to malfunction or reduced lifespan. It can also apply to a workplace, and the humans who work there: fans and air conditioning help keep people cool, comfortable, healthy, and productive.

Effective thermal management helps maintain optimal performance and extends the durability of the products. Without your work (and our parts!), your products probably wouldn’t last long, and might even be dangerous to use.

Passive vs. Active Components

Thermal management products broadly fall into two categories: passive and active. Both are concerned with transferring heat using the physical modes of conduction, convection, or radiation.

Passive thermal management solutions rely on natural heat dissipation methods, such as heat sinks, heat pipes, and natural convection, to manage temperature without requiring additional energy.

Active thermal management solutions, on the other hand, use external energy sources like fans, pumps, or thermoelectric coolers to enhance heat transfer and maintain optimal temperatures in high-performance or high-heat applications.

Getting The Right Thermal Management Product Quickly

In manufacturing, thermal engineers working on product designs face several unique challenges when sourcing thermal management components and systems.

First and foremost is integration with design constraints. Engineers often need to fit thermal management solutions into compact and complex product designs without compromising performance. This requires components that are not only effective but also adaptable to limited space and unusual geometries. It can be difficult—or at least very time-consuming—to find a manufacturer whose product meets spec. But skip straight to a custom part, and you can quickly run up cost.

Plus there’s compatibility to consider: engineers must ensure that the thermal management solutions do not react negatively with other materials, causing material degradation and/or safety hazards.

Material quality and reliability are another factor when sourcing thermal management parts. Reputation of the manufacturer is one way to vet suppliers, but reputations are only reliable if they are relevant to your application and based on consistent results. Even so, an engineer must determine in a limited amount of time, and often from biased sources, whether a part will be high-quality and dependable.

Then there’s cost. Engineers have to balance the efficiency of thermal solutions with budget constraints. They may struggle to find high-performance components that are also cost-effective—and also available within an allotted time-frame—leading to compromises that can impact the overall effectiveness of the thermal management system.

Let a Manufacturers Sales Rep Help You With Thermal Solutions

Suffice it to say, thermal engineers look—quickly—for innovative and cost-effective solutions that will integrate into their designs while providing reliable and efficient thermal management.

If you’re a thermal engineer, or an engineer working on a project that requires you to find a new or better source for thermal management, we urge you to develop a relationship with a local manufacturers sales rep.

Whether you’re looking for fans and blowers, heat sinks or dispensable gap fillers, at Arkco Sales, we are proud to represent a diverse portfolio of leading global manufacturers in thermal management solutions. We’ve been an invaluable resource to OEMs and distributors for nearly fifty years for a few good reasons:

- Innovative and high-performance manufacturers - From the cutting-edge technology of Laird’s Tputty™ 910 to the energy efficiency of ebm-papst’s EC fans, ArKco brings you to the forefront of advanced materials and systems that enhance thermal performance and energy efficiency

- Access to both custom and integrated solutions - Manufacturers like Laird Dupont, nVent Schroff, Mersen, and Laird Thermal Systems provide customized thermal assemblies and materials, ensuring optimal performance for unique applications—while our diverse line card enables us to offer integrated thermal management solutions for various industries

- Comprehensive support and expertise - We listen to what engineers have to say—and we respond quickly and intelligently. And our decades of experience with some of the world’s biggest manufacturers gives us the technical expertise you can rely on to support your applications

If you have a question or feedback, we’d love to hear from you! Email us at arkco@arkco-sales.com or give us a call at (651) 777-7454.

Thermal Management Products

Fans and Blowers

Fans and blowers are essential for maintaining airflow and cooling in a wide range of applications. They come in various types, each suited for specific needs. Both are used to move air, but the primary difference lies in the pressure and volume of air they handle.

Fans generate a low pressure and move large volumes of air. They are typically used for cooling and ventilation, where the main goal is to circulate air within a space or to push air through a system. Fans are generally designed with blades that rotate around a central hub, creating airflow perpendicular to the axis of rotation.

Blowers, on the other hand, are designed to produce higher pressures compared to fans. They move air in a specific direction, often through a duct or to a particular point. Blowers are used when there is a need for a concentrated and directed airflow. They typically feature impellers that draw air in and push it out at a higher velocity through a small outlet.

- Axial Fans - Designed to move air parallel to the fan's axis, axial fans are commonly used in applications requiring high airflow with low pressure, such as HVAC systems and cooling electronic equipment. They are efficient and effective for moving large volumes of air in environments where low-pressure air circulation is needed. Recommended manufacturer: ebmpapst (nVent Schroff also designs and manufactures AC and DC fans specifically for 19-inch electronics racks)

- Centrifugal Fans - move air perpendicular to the fan's axis, creating higher pressure compared to axial fans. These fans are ideal for ducted applications and situations requiring significant airflow over long distances. They are commonly used in ventilation systems, air handling units, and industrial processes where air needs to be moved through ducts or filters. Recommended manufacturer: ebmpapst

- Blowers - used for applications needing higher pressure than axial fans can provide. They are designed to move air or gas in a specific direction and are commonly used in industrial processes, machinery cooling, and HVAC systems that require precise air movement. Blowers are effective in applications where a focused and directed airflow is necessary to achieve optimal performance. Note that blowers may also be used for heating and hot air applications. Recommended manufacturer: ebmpapst

- High Volume Low Speed (HVLS) fans - designed to move large volumes of air at low rotational speeds. These fans typically have a diameter of seven feet or more and are used to create a gentle, even airflow over large areas. HVLS fans are highly energy-efficient and are commonly used in large spaces such as warehouses, gymnasiums, factories, and agricultural facilities. Recommended manufacturer: Fantastic

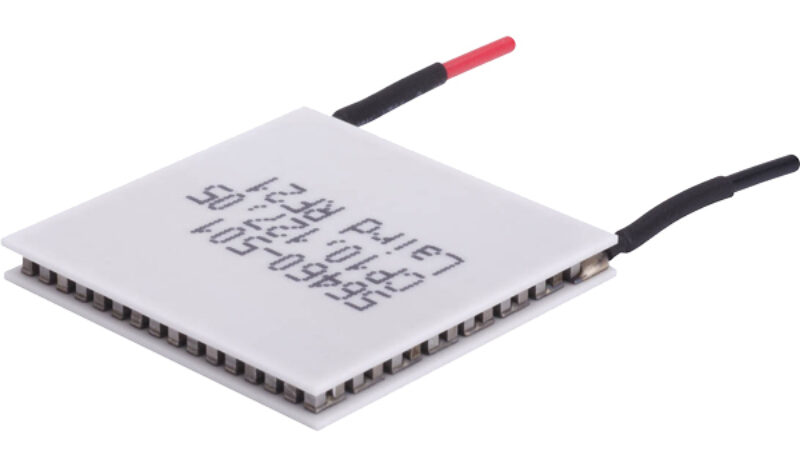

Thermoelectric Coolers

Thermoelectric coolers (TECs) are devices that use the Peltier effect to create a heat flux between two different materials. They are highly effective for applications requiring precise temperature control.

- Single-Stage TECs - Suitable for moderate cooling requirements and widely used in consumer electronics, medical devices, and laboratory equipment. Recommended manufacturer: Laird Thermal Systems

- Multi-Stage TECs - Designed for applications needing significant cooling capacity at very low temperatures, commonly found in scientific instruments and aerospace applications. Recommended manufacturer: Laird Thermal Systems

- Thermoelectric Cooler (TEC) Assemblies - integrated systems, such as Peltier air conditioners, Peltier plate assemblies, benchtop recirculating chillers, and liquid heat exchangers, that combine thermoelectric modules (TECs) with heat sinks and other components, providing more comprehensive cooling solutions compared to single-stage or multi-stage TECs. Recommended manufacturer: Laird Thermal Systems

Heat Sinks

Heat sinks are passive thermal management components (heat exchangers, technically) designed to dissipate heat from electronic devices and other heat-generating components.

How Heat Sinks Work

A heat sink’s primary function is to increase the surface area in contact with the cooling medium—usually air—to efficiently transfer heat away from the device, thereby preventing overheating and maintaining optimal performance.

Heat sinks typically feature a series of fins or pins made from materials with high thermal conductivity, such as aluminum or copper. These fins increase the surface area available for heat dissipation.

The design allows for maximum airflow around the heat sink, enhancing the cooling effect. The heat generated by the electronic component is transferred to the heat sink, which then disperses it into the surrounding air, either passively or with the aid of a fan to accelerate the process.

Mersen manufactures a variety of heat sinks tailored for different applications and industries:

Air-Cooled Heat Sinks

These include extruded and bonded fin heat sinks, designed to operate with natural convection or forced air to dissipate heat.

Extruded heat sinks are made by extruding aluminum or copper, due to their excellent thermal conductivity (and, in the case of aluminum, its light weight). These heat sinks are ideal for general electronic cooling applications, such as in power electronics, motor drives, and LED lighting. The extrusion process allows for complex fin designs that enhance heat dissipation.

Bonded fin heat sinks meanwhile are designed for applications requiring higher thermal performance. These heat sinks are made by bonding individual fins to the base, typically using a high thermal conductivity adhesive. This design allows for more fins and tighter spacing, providing a greater surface area for heat dissipation. They are commonly used in high-power density applications where space is limited.

Liquid-Cooled Heat Sinks

Also known as cold plate heat sinks, these use liquid coolant to enhance heat transfer from high-power devices.

Mersen's cold plate heat sinks are designed for liquid cooling systems. They incorporate channels or passages within the heat sink through which a cooling liquid is circulated, providing efficient heat removal from high-power devices.

Cold plates are particularly useful in applications such as electric vehicle power modules, renewable energy systems, and high-performance computing.

Heat Pipe Heat Sinks

Heat pipe heat sinks, or “hybrid” heat sinks, combine the principles of both air- and liquid cooling to achieve superior thermal performance.

These heat sinks utilize pipes to transfer heat from the source to the fins more efficiently. Heat pipes contain a working fluid that vaporizes at the hot end and condenses at the cooler end, providing highly efficient thermal conductivity.

Mersen’s heat pipe heat sinks are suitable for applications requiring rapid heat removal and uniform temperature distribution, such as in telecommunications and data centers.

Thermal Interface Materials (TIMs)

Thermal interface materials, or TIMs, are used to enhance the thermal coupling between heat-generating components and heat sinks or other cooling devices. They ensure efficient heat transfer and come in many forms.

Laird Dupont—formerly Laird Performance Materials—offers a range of TIMs tailored for efficient thermal management in various applications:

- Thermal Pads / Gap Pads / Dielectric Pads – These gap fillers provide a compliant interface between components, combining high thermal conductivity with excellent dielectric strength to ensure electrical insulation while transferring heat. They are typically used in telecom and power conversion equipment, where maintaining electrical isolation is as important as thermal management. Laird Dupont, our recommended manufacturer, also designs and manufactures a variety of unique speciality thermal pads and foam gaskets, such as their popular CoolZorb line.

- Thermal Tapes - These pressure-sensitive adhesives provide strong adhesion and consistent thermal performance, simplifying the attachment process. They are particularly useful in applications where space is limited and ease of assembly is crucial, such as LED lighting and consumer electronics.

- Thermal Greases - High viscosity thermal greases fill microscopic air gaps between surfaces to enhance heat transfer, ensuring efficient cooling. They are often used in high-performance applications like CPUs and GPUs in computers, where maximizing thermal conductivity is essential.

- Dispensable Liquid Gap Fillers / Thermal Gels – viscous liquids designed to conform to complex surfaces and fill large gaps, providing efficient thermal transfer and mechanical cushioning. They can be easily dispensed into intricate assemblies, making them ideal for applications with varying gap sizes and shapes. Their versatility and ease of application make them suitable for use in automotive electronics, telecommunications equipment, power modules, and handheld gaming systems, where precise and adaptable materials are needed for fragile components prone to vibration, design density, and high operating temperatures. Examples include Laird’s Tflex, Tgel, and Tputty.

- Thermal Adhesives - Epoxy and silicone-based adhesives provide both mechanical bonding and thermal conductivity, offering robust attachment and heat dissipation. These materials are critical in aerospace and military applications, where components must endure extreme conditions and mechanical stress.

- Phase Change Materials (PCMs) - These materials change phase—are solid at room temperature but become fluid at higher temperatures—effectively managing heat spikes. They adapt to thermal cycles, making them ideal for use in high-performance computing and servers, and in high-reliability applications like aerospace and medical devices.

- Advanced Materials - Pyrolytic graphite provides thermal anisotropy, offering exceptional in-plane thermal conductivity while remaining lightweight and flexible. These properties make it ideal for high-end consumer electronics and smartphones, where efficient heat spreading and compact design are crucial.

Recommended Manufacturer: Laird Dupont

Liquid Cooling Systems

Liquid cooling systems are advanced thermal management solutions used when air cooling is insufficient to handle high thermal loads.

These systems are designed to transfer heat away from critical components using a liquid coolant, which can absorb and dissipate heat more effectively than air. They are essential in maintaining optimal operating temperatures for high-power applications, ensuring reliability and performance.

Recirculating chillers refrigerate a liquid coolant to a set temperature. This coolant is then circulated to absorb heat from electronic components. They are closed-loop systems that continuously circulate coolant to maintain a stable temperature. Chillers are designed for precise thermal management and are commonly used in laboratory equipment, analytical instruments, and medical devices that require consistent cooling.

Typical applications include medical imaging equipment, industrial lasers, and semiconductor manufacturing, where precise temperature control is crucial. Laird Thermal, our recommended manufacturer, offers the Nextreme™ series of next-generation liquid recirculating chillers, as well as custom cabinet chillers

Unlike chillers, heat exchangers transfer heat between the water coolant and another medium, usually air, typically using a system of tubes or plates.

These systems are highly efficient and offer a compact solution for dissipating large amounts of heat. Typical applications include HVAC systems, industrial machinery, and power generation, where reliable and effective thermal management is required.

Laird Thermal offers a variety of water heat exchangers for industrial, medical, and labrotory applications. For electronics, computing, and datacenter applications, nVent Schroff makes rear-door, in-row, and in-rack heat exchangers for electronics cabinets and racks.

When freezing or corrosion is a concern, these systems transfer heat between an oil coolant (instead of water) and another medium, often using a finned or plate structure to maximize surface area for heat transfer.

They are typically used in hydraulic systems, heavy machinery, and transformers, where high thermal loads must be managed in challenging environments and where maintaining oil purity is crucial.

Laird Thermal Systems designs custom liquid cooling systems to manage heat in high-power applications where air cooling is insufficient.

These systems are tailored to specific needs, utilizing water, water-glycol, or transformer oil coolants, and can include features like multiple liquid circuits, PID temperature control, and variable pump capacities. They provide precise temperature control and high efficiency, making them suitable for medical diagnostics, industrial x-ray equipment, and sample storage compartments.

Their systems ensure reliable performance under various pressure conditions, enhancing the durability and stability of sensitive equipment.

Recommended Manufacturer: Laird Thermal Systems (for electronics cabinet/rack cooling: nVent Schroff

Rack and Enclosure Cooling

Rack and enclosure cooling solutions are critical for maintaining optimal operating conditions for sensitive electronic equipment:

Solutions such as Coolant Distribution Units (CDUs), play a crucial role in liquid-cooled data centers by distributing liquid coolant to manage heat dissipation effectively. These units work by circulating coolant through a network of tubes and heat exchangers attached to the rear doors of server racks. This setup allows the removal of heat directly from the servers, maintaining optimal operating temperatures.

Typical use cases include high-performance computing environments where efficient heat management is essential to maintain server performance and reliability. An example is the RackChiller CDU800, which features a redundant pump system, integrated leak detection, and remote control capabilities, making it a robust choice for maintaining stable temperatures in data centers.

Products such as water heat exchangers, are designed to cool specific rows of server racks by transferring heat from the hot air exhausted by the servers to the coolant. These systems are placed between server racks and utilize liquid cooling to provide precise temperature control.

This method is particularly effective in data centers with high-density server configurations, where traditional air cooling methods might fall short. The RackChiller RDHX PRO, for instance, offers active cooling with options for top or bottom coolant feed and integrates an intuitive touch panel display, making it suitable for managing the thermal demands of densely packed server environments.

Products like 19" rack fan trays provide targeted airflow within server racks. These fan trays are equipped with multiple fans that enhance air circulation around electronic components, preventing overheating.

They are typically used in data centers, network cabinets, and other electronic enclosures where efficient heat removal is critical to maintaining equipment performance. DC fans available in various sizes and voltages are common choices, providing flexibility to match specific cooling requirements. These fans ensure that hot spots are eliminated and that components operate within safe temperature ranges.

Sometimes heat and not cooling is needed. Enclosure heaters are essential for maintaining optimal temperatures inside enclosures, particularly in environments prone to condensation and low temperatures. These heaters ensure that electronic components remain within their operational temperature ranges, preventing moisture-related damage and ensuring reliable performance.

Common applications include telecom cabinets, outdoor enclosures, and industrial control panels. Products like thermostats and hygrostats from nVent Schroff offer precise temperature and humidity control, allowing for easy assembly and integration into existing systems. These control modules help maintain the necessary environmental conditions to safeguard sensitive electronic equipment.

Recommended manufacturer: nVent Schroff

Thermal Management Products by Industry

Here's a detailed overview of the specific thermal management parts, systems, and products offered by each manufacturer across various industries, with sample applications:

Agriculture/Livestock Industry

- Axial fans and centrifugal blowers for greenhouse ventilation and livestock barn cooling, ensuring optimal airflow and temperature control. ebm-papst

- Enclosure cooling systems such as filtered fans and air conditioners to protect electronic control systems used in agricultural monitoring and automation. nVent Schroff

- HVLS fans for air destratification in barns, humidity and temperature control, ventilation, and seasonal energy savings. Fantastic

Appliances Industry

- Compact AC and EC fans for cooling in refrigerators, ovens, and dishwashers to ensure efficient operation and longevity of the appliances. ebm-papst

- Thermal interface materials (TIMs) like thermal pads and gap fillers to manage heat in high-power components such as heating elements and control boards. Laird DuPont

Electric Vehicle Industry

- Thermoelectric coolers and heat exchangers to regulate battery temperatures and power electronics in electric vehicles, enhancing performance and safety. Laird Thermal

- Laminated bus bars and liquid-cooled cold plates for thermal management in EV battery packs and inverters, ensuring efficient heat dissipation. Mersen

HVACR Industry & Mechanical Contractors

- HVLS fans for consistent temperature, year-round comfort, humidity control, and seasonal energy cost savings. Fantastic

- Ceiling and exhaust fans for residential and commercial HVAC systems to maintain air circulation and reduce heat buildup. ebm-papst

- Enclosure air conditioners and heat exchangers to protect HVAC control units and electrical panels from overheating. nVent Schroff

Heavy Machinery Industry

- High-performance radial and axial fans for cooling engines and hydraulic systems in heavy machinery, providing reliable temperature control under demanding conditions. ebm-papst

- Power electronic cooling systems including air-cooled heat sinks and liquid-cooled cold plates for use in industrial machinery and heavy-duty equipment. Mersen

IT Industry & Data Centers

- Rear-door heat exchangers, in-row coolers, and in-rack fan trays to manage heat in high-density server racks and data center infrastructure. nVent Schroff

- High-performance thermal interface materials (TIMs) and gap fillers to ensure efficient heat dissipation from processors and electronic components in data centers.

- Thermoelectric coolers (TECs) for optical transceivers in fiber optic telecommunication networks. Laird Thermal

Industrial Equipment Industry

- Thermoelectric coolers and circulating chillers for machinery producing high heat, such as lasers, additive manufacturing, machine vision systems, infrared sensors, and semiconductor manufacturing. Laird Thermal

- Industrial-grade blowers and fans for cooling electronic control panels and machinery, ensuring operational stability and longevity. ebm-papst

- Enclosure cooling systems such as air conditioners and heat exchangers to maintain optimal temperatures for industrial automation systems and electronic controls. nVent Schroff

Marine/RV Industry & Recreational Equipment

- HVLS fans for warehouse applications, providing effective cooling and ventilation through cost-saving air destratification. Fantastic

- Thermal tapes and pads to manage heat in electronic devices and control systems used in RVs and boats. Laird DuPont

Medical Device Industry

- Precision thermoelectric coolers and custom liquid cooling systems for cooling diagnostic equipment, imaging devices, and patient monitoring systems. Laird Thermal

- Compact enclosure cooling solutions such as fan trays and heat exchangers to maintain reliable operation of medical electronic enclosures. nVent Schroff

Military & Aerospace Industry

- High thermal integrated conduction-cooled assemblies (CCAs), coolant distribution units (CDUs), and sawtooth Card-Loks for VPX systems used in military and aerospace applications, ensuring rugged and reliable thermal performance. nVent Schroff

- Advanced thermal interface materials (TIMs), phase change materials, and high-performance thermal greases to manage heat in avionics and defense electronics. Laird DuPont

Power Generation Industry

- Air-cooled heat sinks and liquid-cooled cold plates for thermal management in power converters, inverters, and other power generation equipment. Mersen

- Cooling fans for generators and power electronics to ensure efficient operation and prevent overheating in power generation systems. ebm-papst

Transportation & Rail Industry

- Direct-to-chip liquid cooling systems and cold aisle containment solutions to manage heat in rail signaling equipment and on-board train control systems. nVent Schroff

- Thermal management materials such as thermal interface pads and phase change materials to cool electronic components in transportation systems. Laird DuPont

Solar Energy Industry

- High-performance air-cooled heat sinks, heat pipe assembly heat sinks, embedded heat pipe air-cooled heat sinks, and liquid-cooled cold plate heat sinks for inverters, junction boxes, and power conditioning systems in solar energy installations, ensuring optimal performance and efficiency. Mersen

- Thermal interface materials (TIMs), and thermally conductive adhesives and tapes for power inverters, junction boxes, and other electronic components within solar panels; phase change materials (PCMs) for power electronics within solar energy installations—and in battery energy storage systems—to manage temperature fluctuations and prevent overheating during peak power generation times; and graphite heat spreaders for dissipating heat from hot spots in solar power inverters and other high-power electronic components. Laird DuPont

Beyond Thermal Management…

ArKco Sales is your guide and source for electromechanical systems and components across a broad range of industries and applications. In addition to thermal management, we provide expertise and connect you with manufacturers in the following categories:

Contact Us

Many websites say, “don’t hesitate to contact us.” We say: do as you please!

In addition to the content posted here, we also produce a wide variety of high-quality quarterly newsletters that feature the latest products from our manufacturers, new and interesting design considerations and applications, technical articles, and other interesting content aimed at engineers working on product design. Sign up now, and unsubscribe any time if you don't like them!

Here’s our contact info:

+1 (651) 777-7454

arkco@arkco-sales.com

Online contact form

Why Work With A Sales Rep?

The number one reason you might want to reach out to one of our sales reps is that you are working on a project design—whether in early prototyping stages or late in testing—and you need a part, assembly, or whole system.

- You want to know what’s available right now

- You want to know if it’ll work with your design

- You want to know if it’ll do the job well … or well enough

- You want to know the price

AI tools are getting better all the time, and we at ArKco are working on mastering it. In the meantime, you can rely on our reps to get you the answers you need quickly. Even if it means we have to refer you to someone else.

If you are looking for the best thermal management solutions for your projects, our team is here to help you find the right products and solutions to meet your specific needs.

Check Inventory

For availability and inventory details, please visit our trusted parts inventory link: Check Inventory